Plastic processing from A to Z

Plastic is one of the most practical, versatile and affordable materials available. It is not surprising that it is quickly becoming preferable to use plastic for the creation of parts for devices and semi-finished products. However, plastic machining remains a profession in its own right. Thanks to our passion for the profession, we know better than anyone which types of plastics and processes are best used for the desired applications.

We are flexible, act quickly and are happy to collaborate with you. In addition, we work with the highest-rated machines in the industry and only process the best plastics. In addition, we will deliver the finished product to you promptly, as agreed!

- We process all types of plastics

- Small or large, short or long, serial or a large run: anything is possible!

- Accurate tolerances and difficult-to-machine plastics go hand in hand

- Surface treatments, such as vapor deposition of gold or silver layers, are also possible!

- We routinely supply CoCs with your products

Existing design or nothing on paper yet

Every plastic processing starts with the end product. What exactly do you need and what specifications must it meet? Based on this, we choose the right way of processing and the right type of plastic. And we do this whether you already have an existing design or no idea of what exactly you need. We will guide you through this.

Which plastics does Olpa Hank work with?

We process all types of plastics that are available. Think of:

- Basic plastics such as HDPE, PP or PVC

- Engineering plastics such as HMPE, PA and POM

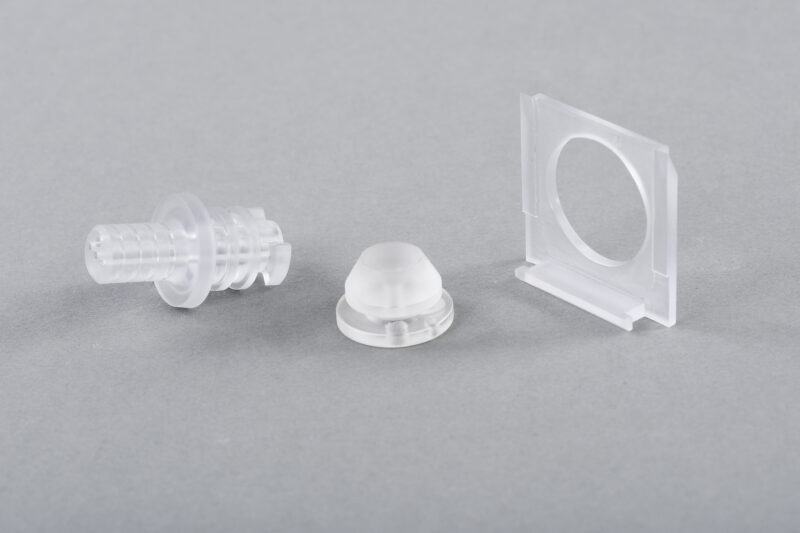

- Clear or glazing plastics such as PC, PMMA and PET

- High performance plastics such as PEEK, PSU, PAI and PTFE

This means that whatever end product you want, whatever specifications it must meet and whatever your further wishes are: we are your partner.

A selection of our plastic processes

Not only will the type of plastic determine the desired result, the form of machining also plays a role. Therefore, we offer various plastic machining services; turning, milling and drilling plastic primarily for fabrications. Depending on your desired end product, we determine the correct processing method.

We have been a supplier to various industries for years

We have proudly supplied plastic semi-finished and finished products to companies from various industries for years. Examples include:

- Sprinkler adapters manufactured from PSU for medical industry

- Heat-resistant nozzles from Torlon (PAI) for the food industry

- HDPE scraper blades that can be used to clean conveyor belts in the agricultural sector

- Insulating spacers made from PES+glass for mechanical engineering

- Hose fittings made from POM for shipbuilding

- Clamp sets made of nickel-plated brass with Nylon screw for display cases in the retail industry

The possibilities are truly endless.

Curious about what we can do for your company? Please feel free to contact us or request a quote without obligation!

The Olpa Hank way of working

From first contact to delivery in just 5 steps.