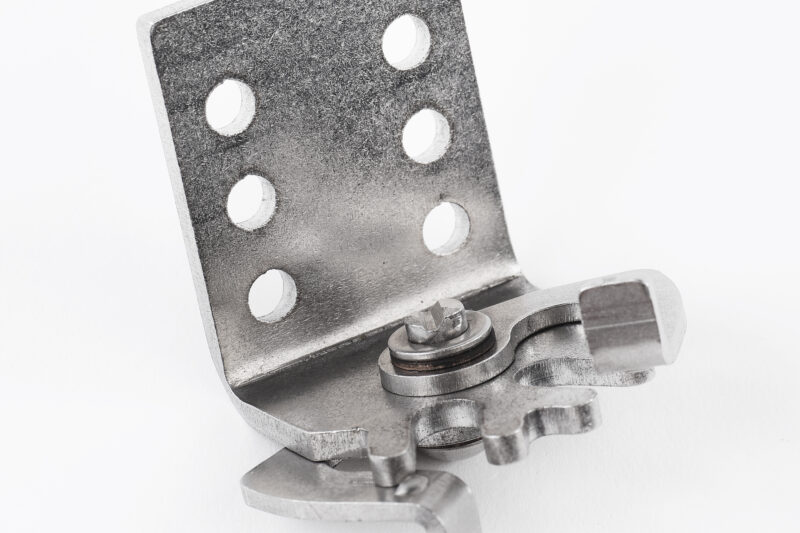

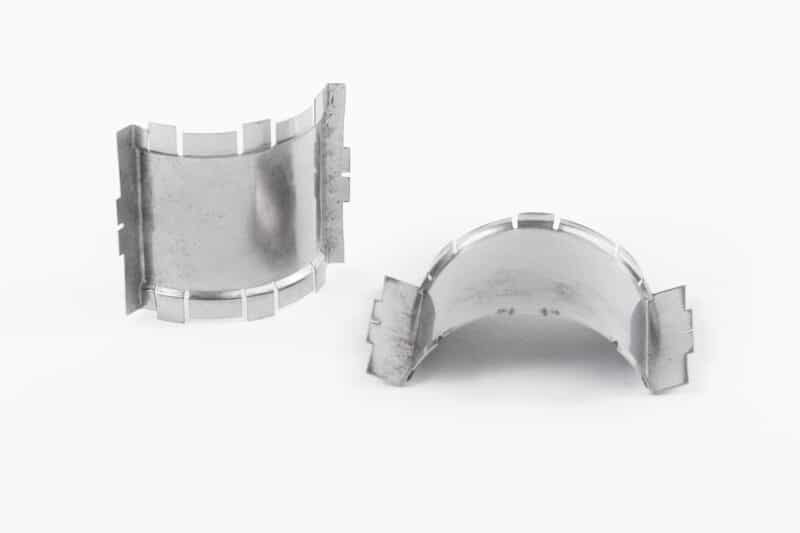

Stamping work

Outsource your stamping work to Olpa Hank. We produce high-quality end products with short lead times. We work accurately, with low tolerances. Our entire process is set up to stamp, die-cut and deliver products to you, the customer, quickly and sustainably. We will take care of all your concerns by proving you with precise industrial machining. We do this with various materials, both metals and plastics. This includes all common metals and plastics, as well as several less common, high-end materials.

Do you need a partner for precise punching or stamping work? Olpa Hank is flexible, precise and quick to change gears. Let us know what you need and we’ll make it happen.

Manufacture of dies for stamping work

The stamping or punching of parts is done using dies. We also manufacture these dies ourselves from hardened tool steel by milling and the use of a spark eroding machine. When manufacturing a die for stamping work, we do not rush into it. With good reason: the quality of the die largely determines the quality of the end product. It is also true that a good die lasts longer, something that leads to greater efficiency, especially with higher production quantities. Nevertheless, quality is the starting point for all our work.

Choose Olpa Hank for stamping work

We have various CNC-controlled presses, hydraulic presses and various other presses with which we carry out stamping and punching work. With specialised machines for every type of processing, we can meet specific customer requirements to the maximum extent, without having to make any concessions. And that is a gratifying science, where precision counts.

The Olpa Hank way of working

From first contact to delivery in just 5 steps.